Design for Manufacturing Analysis

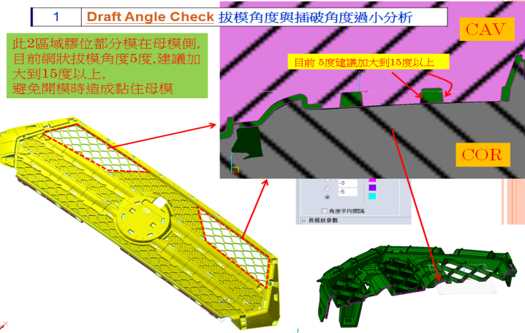

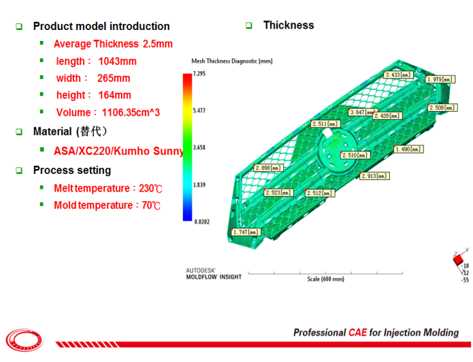

Comprehensive DFM checks on draft, wall thickness and cooling to remove risks early.

Learn moreProfessional Mold Manufacturing | Since 1978

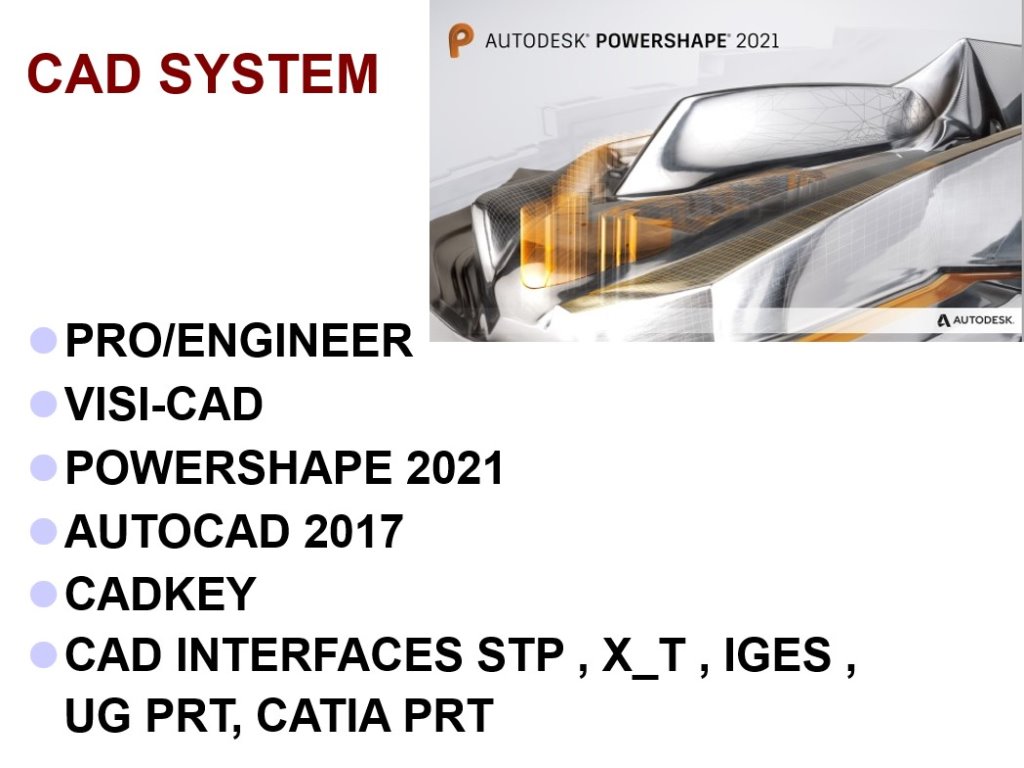

Founded in 1978, BAMWEI specializes in high-quality injection molds and rubber molds, and is recognized as one of the leading professional mold manufacturers in Taiwan. With comprehensive design and manufacturing capabilities, we utilize advanced CAD/CAM systems, precision machining equipment, SODICK EDM machines, and a highly experienced engineering team. From product DFM, mold design, machining processes to trial molding verification, we provide a fully integrated one-stop mold development service.

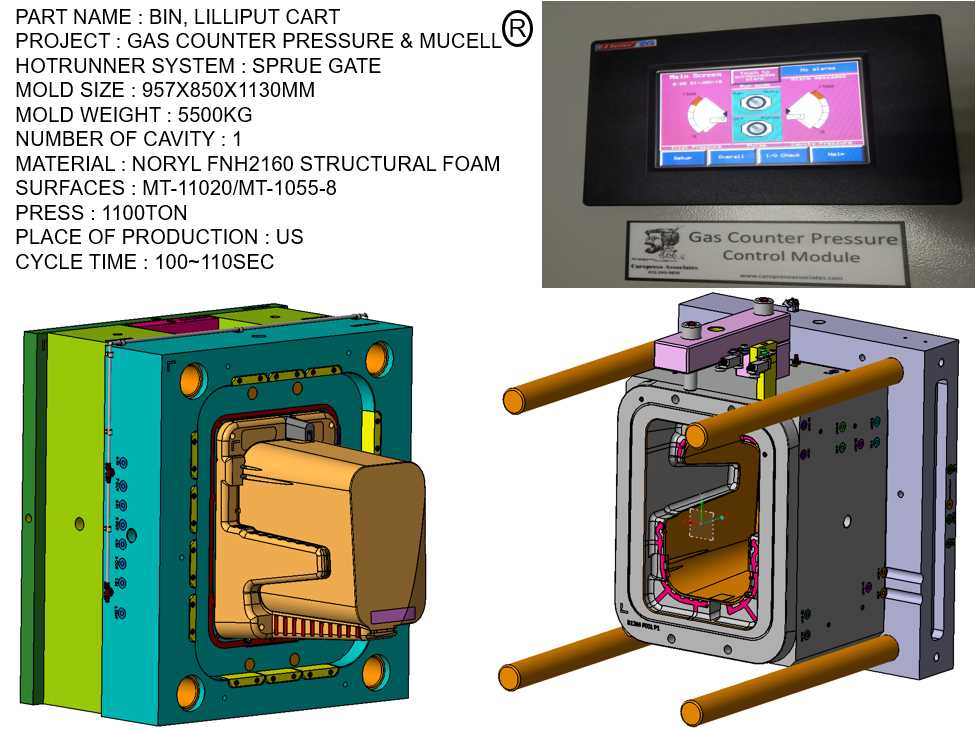

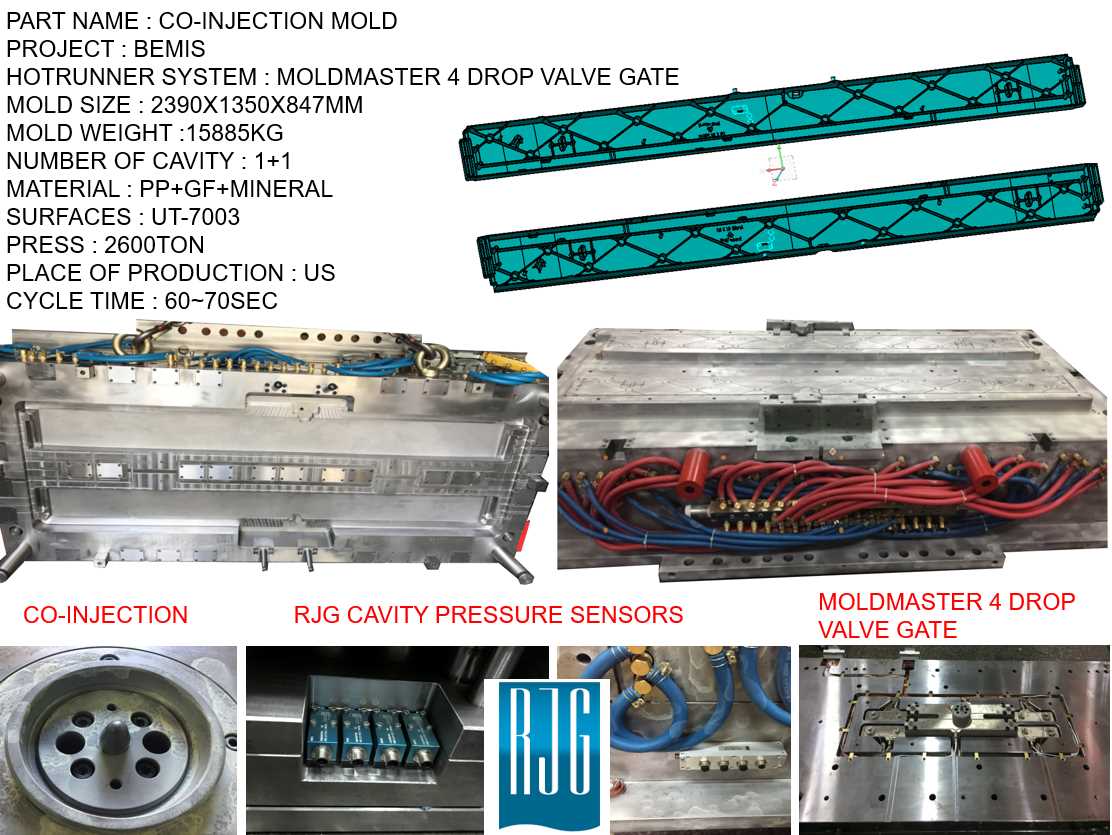

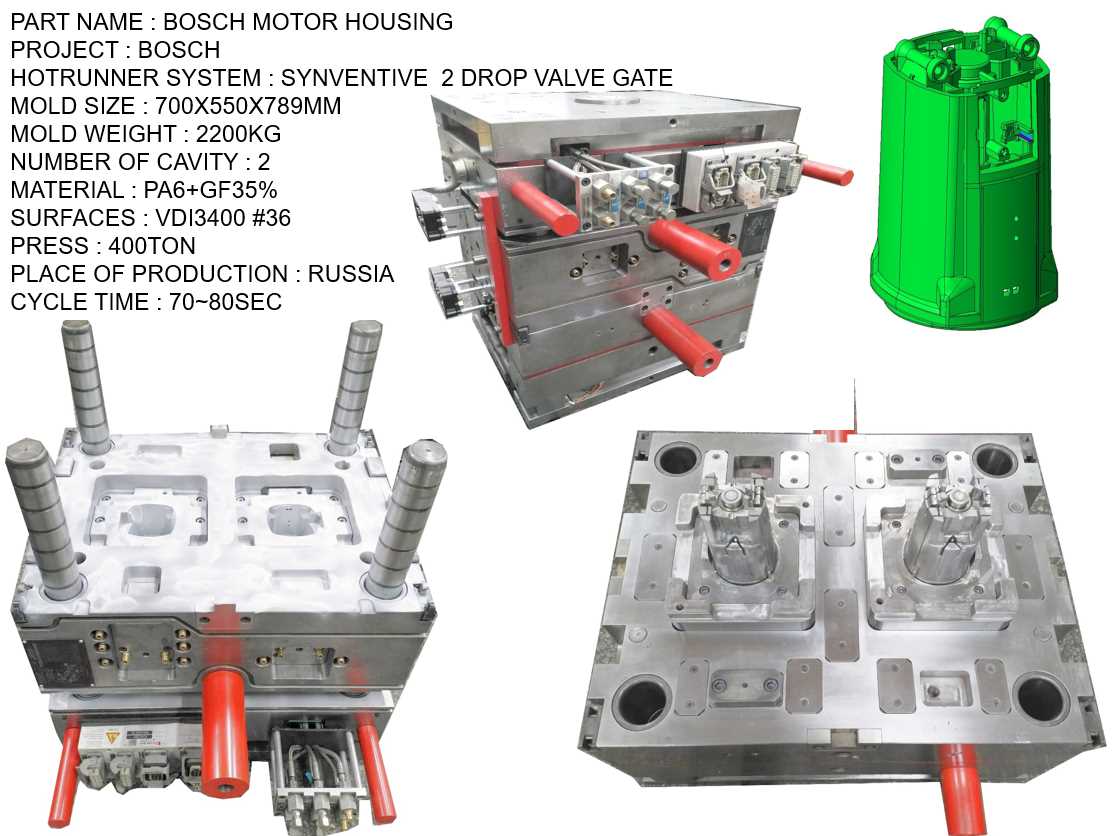

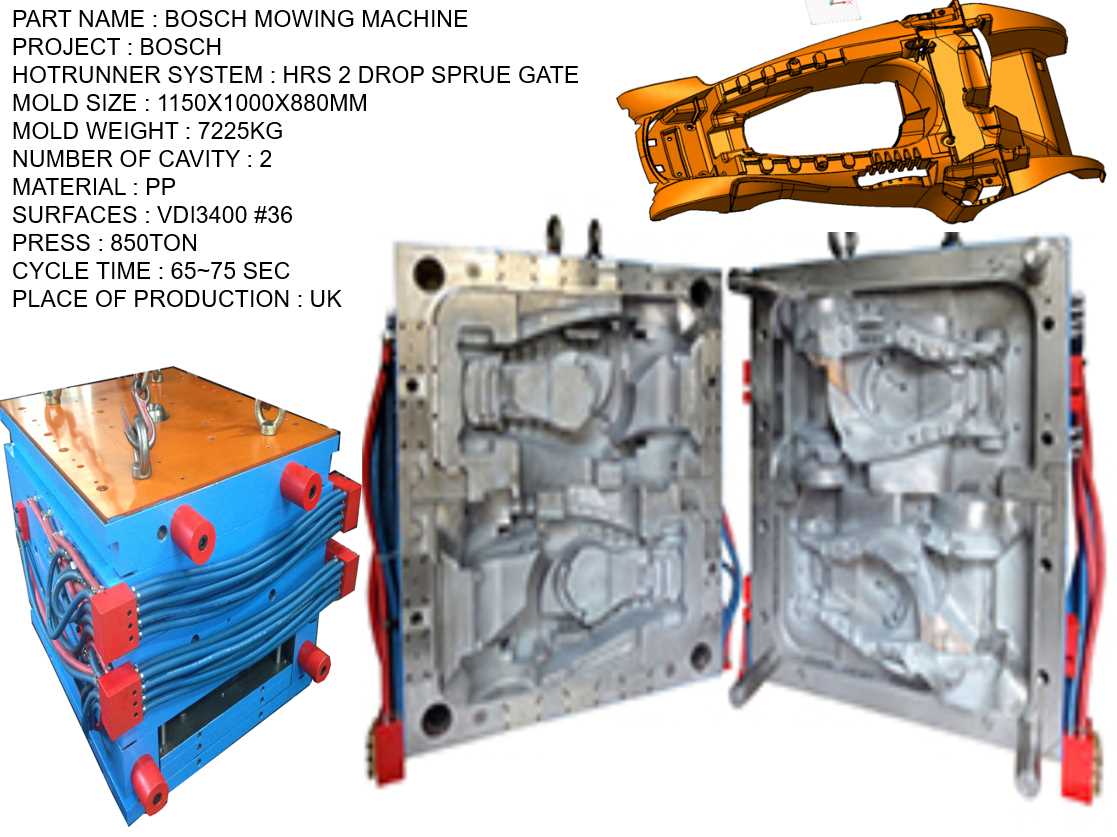

Over the years, we have supplied molds across diverse industries worldwide, including automotive parts molds, gas-assisted and counter-pressure molds, MuCell foam molds, multi-material (Co-Injection) molds, power tool molds, and large structural component molds. Whether for appearance parts, functional components, or highly complex structural parts, we deliver stable quality and precise machining.

With over 40 years of manufacturing experience, we have collaborated with numerous international brands and OEMs, serving customers throughout the United States, Europe, Japan, and beyond. BAMWEI continues to be a trusted mold development partner globally, backed by our reliable manufacturing capability, strict quality control, and commitment to on-time delivery.

Discover BAMWEI in depth

Learn moreProviding comprehensive mold manufacturing solutions

Comprehensive DFM checks on draft, wall thickness and cooling to remove risks early.

Learn more

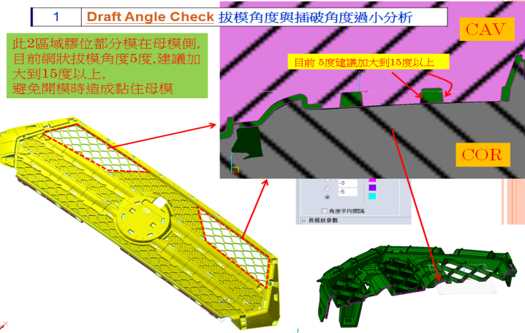

Moldflow simulation of fill time, pressure, weld lines and air traps for predictable quality.

Learn more

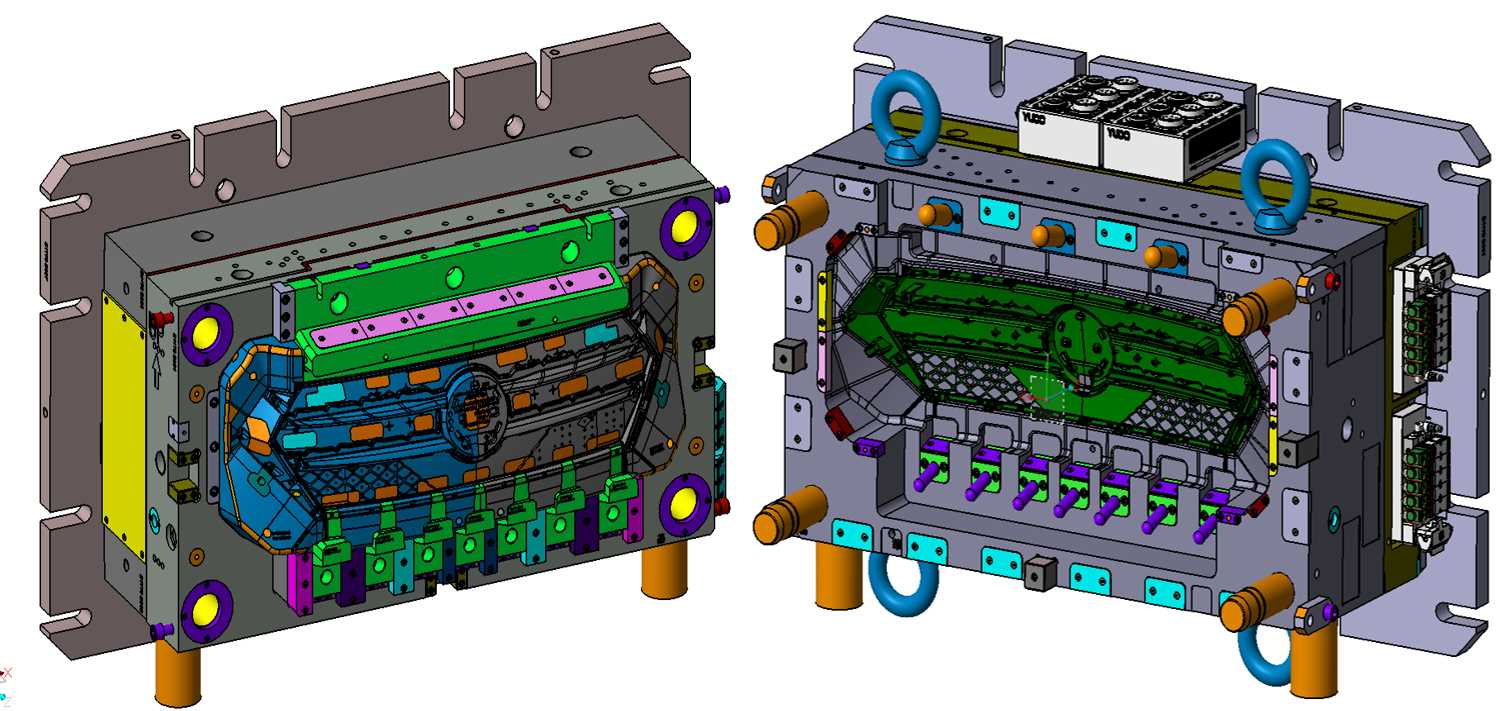

Full 3D mold design covering parting lines, gating, ejector and cooling layouts.

Learn more

CAD modeling, layout and structural evaluation to ensure efficient product design.

Learn more

CAM toolpath planning and automation strategies balancing efficiency and finish.

Learn more

Multiple large machining centers with fixture automation for precise heavy molds.

Learn more

SODICK EDM and related equipment for fine details on hardened components.

Learn more

Wire EDM ensures tight tolerances and clean contours for mold assemblies.

Learn more

AUTOMOBLE PARTS

AUTOMOTIVE LIGHTING

BOTTLE CAP,MULTI CAVITY PARTS

BOXES MOLD

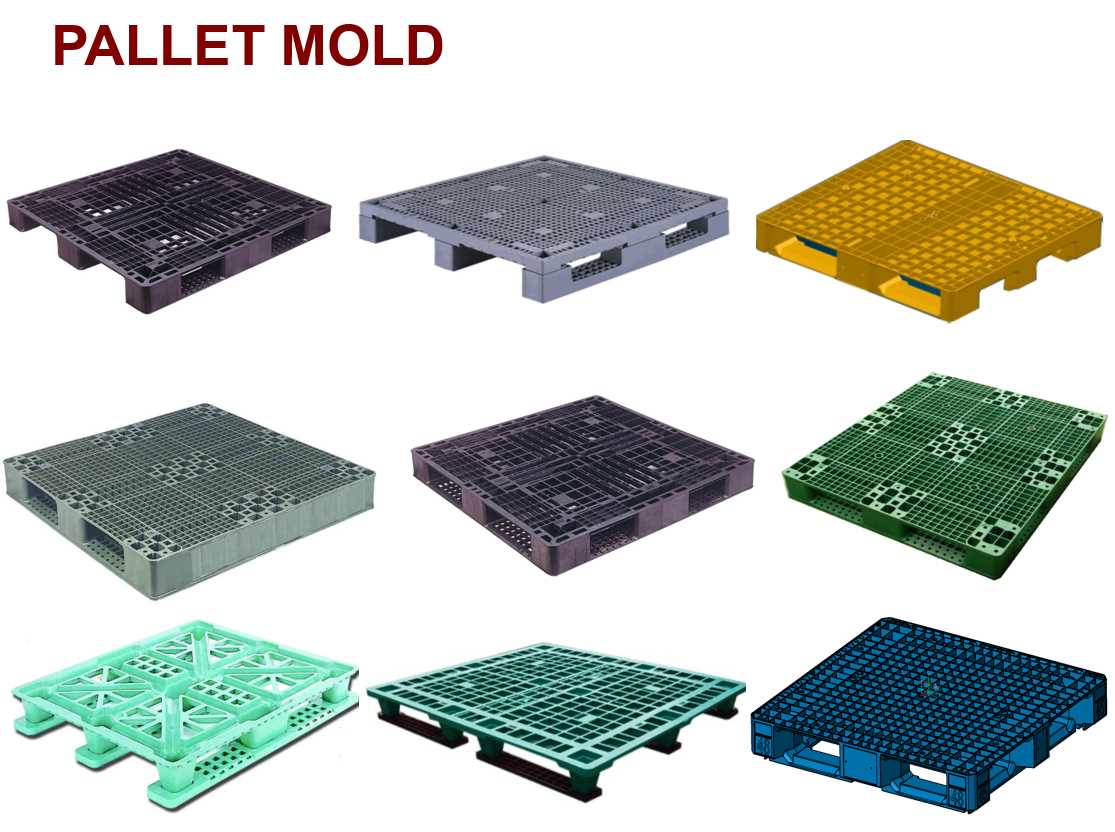

PALLET MOLD

BATTERY BOX MOLD

AUTOMATIC UNSCREW MOLD

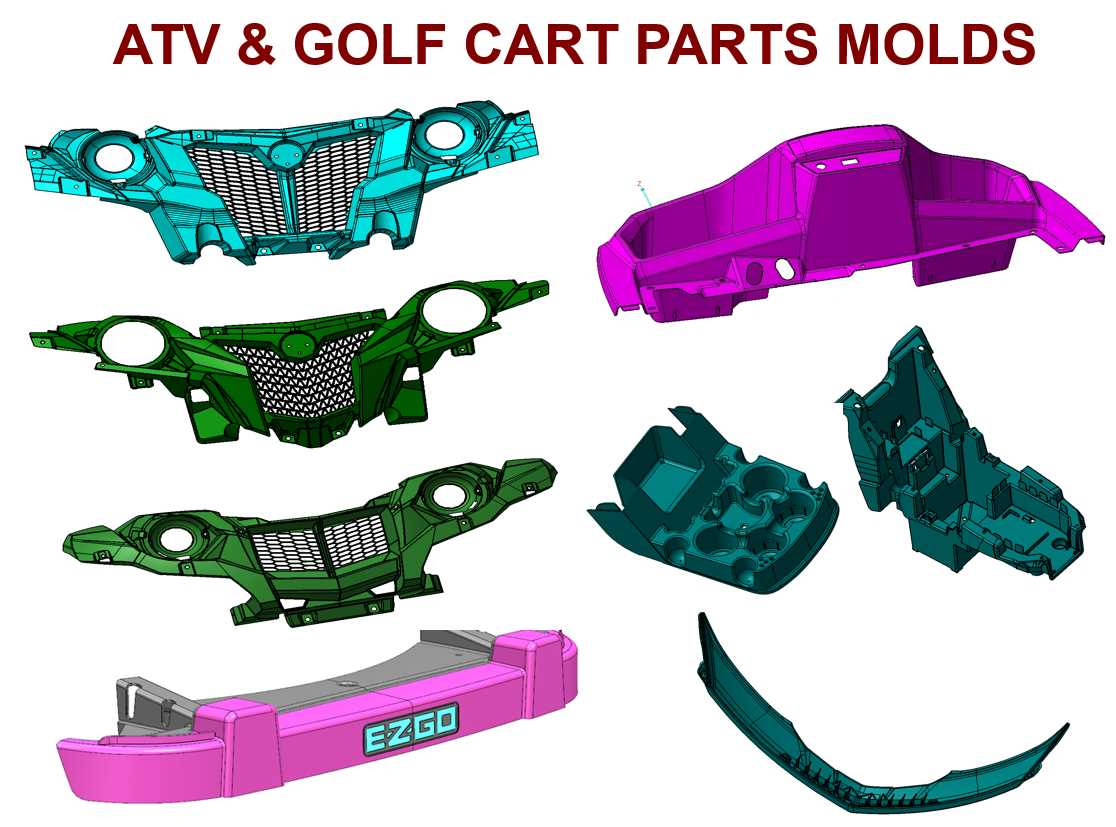

ATV & GOLF CART PARTS MOLD

FLOWERPOT MOLD

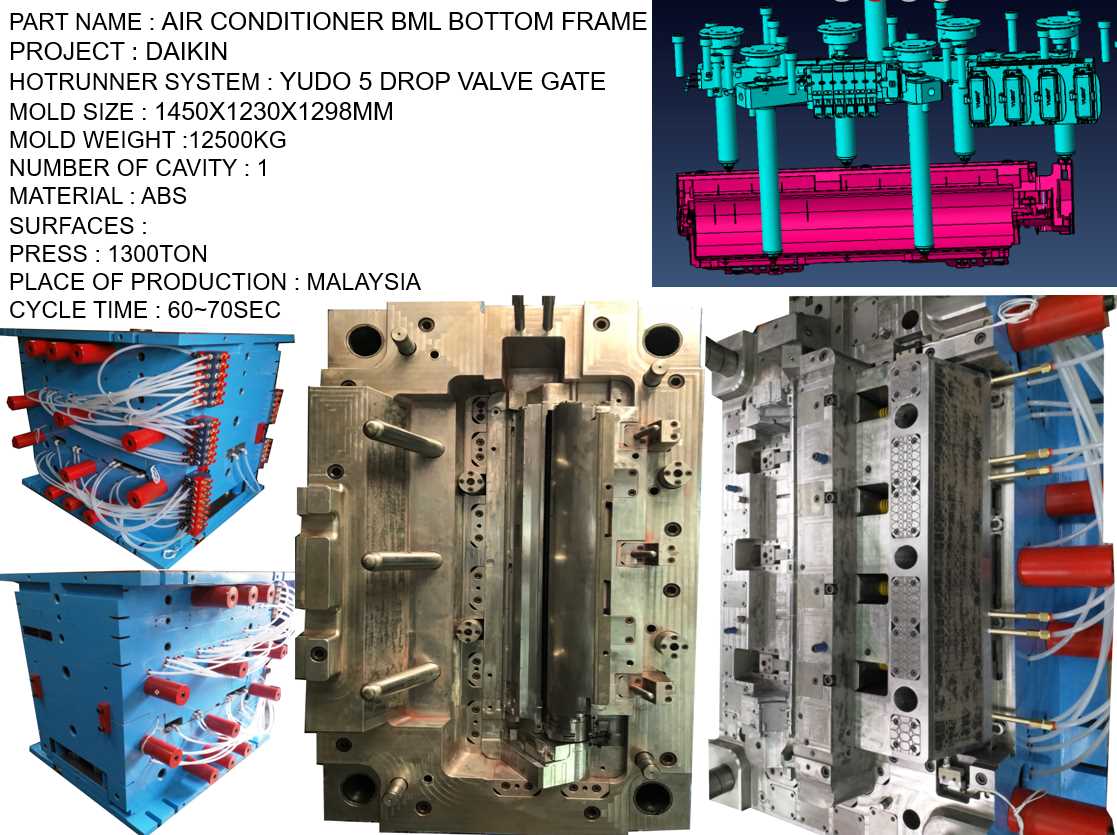

AIR CONDITIONER PART MOLD

GAS COUNTER PRESSURE & MUCELL MOLD

CO-INJECTION MOLD

MOTOR HOUSING MOLD

MOWING MACHINE MOLD

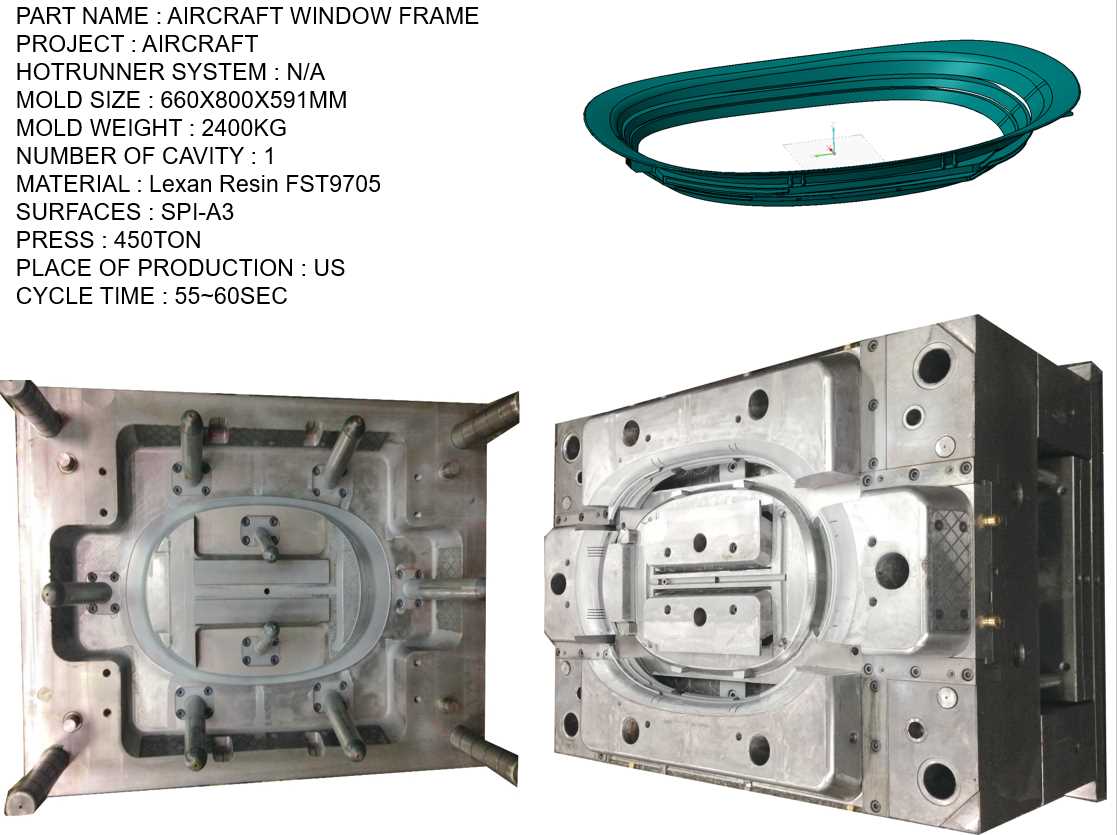

AIRCRAFT WINDOW FRAME MOLD

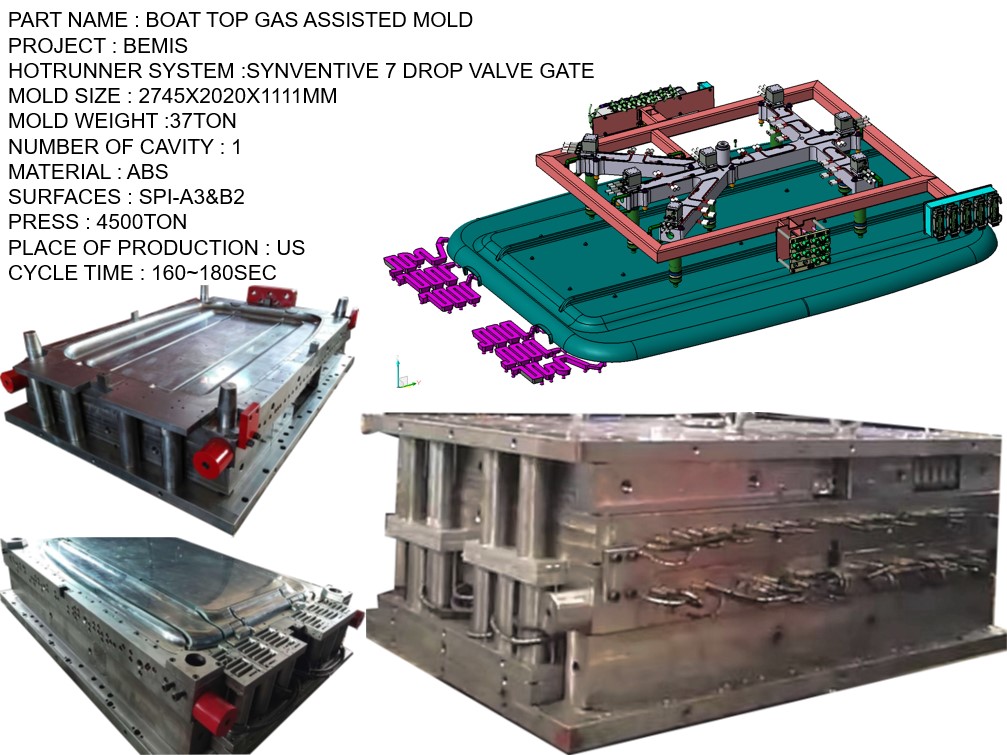

GAS ASSISTED MOLD

Contact us and let us provide you with the best solutions

Contact Us